A while back, in my how to make a wooden wall clock post, I let you in on a little sneak peek of this week’s project. Do you remember seeing a peek of this X Base Console Table?

I just love sneak peeks…it gets people curious and I like to hear their ideas on what they think it is. So, my love for sneak peeks shows up on occasion in my blog posts it seems haha.

.

So back to the table…it’s very similar to the X Base Console Table I built a while back.

But this one has an added shelf and is quite a bit larger. I LOVE the size of this table. The smaller one above is great for an entryway or a smaller space. But this larger one is perfect for living room or bedroom storage for blankets, pillows, baskets, books, whatever really.

.

And I really like the Xs on the side…mostly because it’s really helpful in getting your table square when you build it haha.

It’s a pretty quick and easy build that doesn’t require any fancy tools and you can have done in a few good hours. So are you ready to get building?? Before you get started, you might want to check out this post on how to make your own 2x2s and check out the printable plans here as well:

This post contains affiliate links. See disclosure policy for details.

.

Tools and Materials:

- Miter Saw

- Circular Saw

- Kreg Rip Cut (optional, but helpful)

- Kreg Jig for Pocket Holes

- Drill.

- (8) 2x2x8

- (1) 2x10x8

- (1) 2x8x10

- ½ sheet ¾″ plywood

- 2 ½″ pocket hole screws

- 2 ½″ wood screws

- 1 ¼″ pocket hole screws

- 1 ¼″ wood screws

- Wood Glue

Step 1: Build the X Base Console Table Front and Back Frames

I started by cutting down the 2x2s and building the front and back frames. Cut four 2×2 legs and six 2×2 frame pieces. Then, I used 2 ½″ pocket hole screws and 1 ½″ pocket holes to assemble 2 frames like shown here.

Step 2: Assemble X Base Console Table Front and Back Frames Together

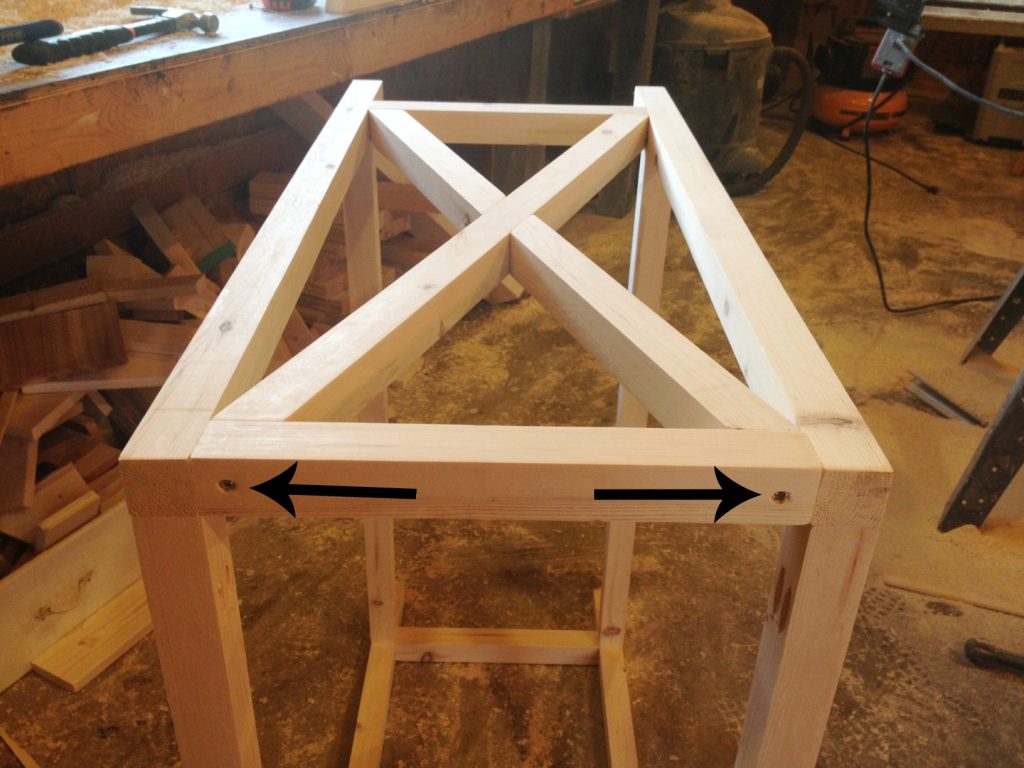

Now that the front and back frames were together, I connected them with four side braces. Again, I drilled 1 ½″ pocket holes in each end and used 2 ½″ pocket hole screws to assemble the base like shown. You won’t add the middle pieces until later.

Step 3: Add the Xs to the Sides of Table

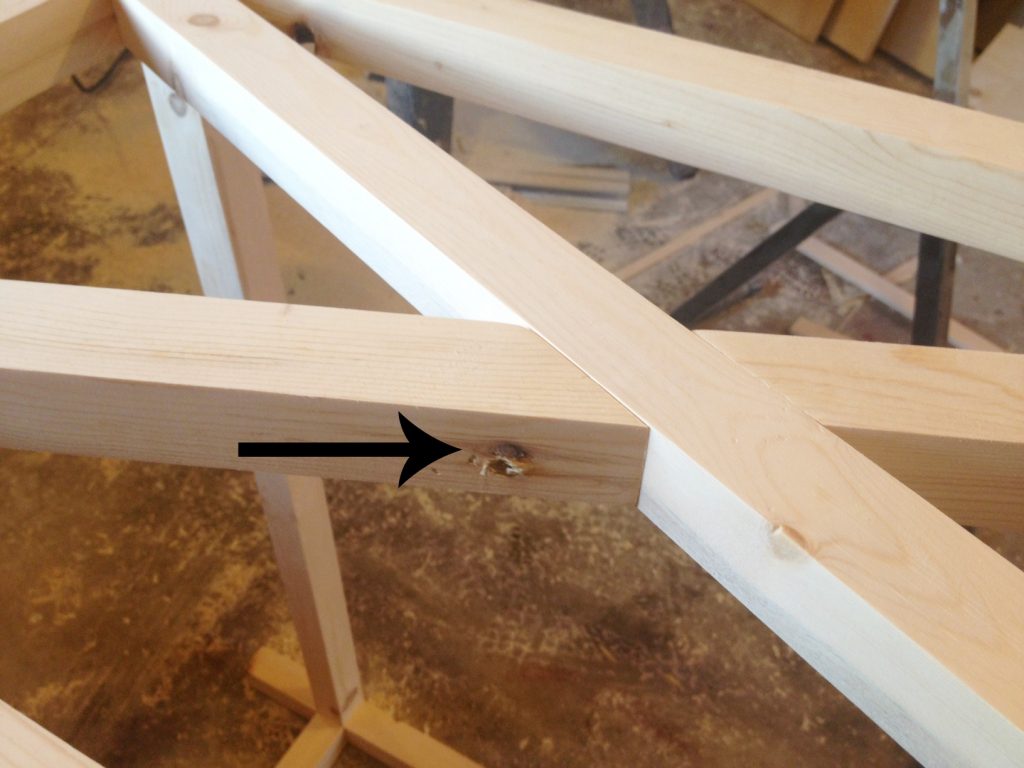

You may find it helpful to refer to this X base console post from a few months back. For the Xs, I think it’s always easiest to cut to fit. But I’ve included dimensions with angles in the plans here to reference.

.

But, to cut to fit, flip the frame over on its side and hold a 2×2 on the frame lining up the edges with the right corners. Make a mark and take it to the miter saw and see which angle it lines up best with. It’s okay if you don’t get it PERFECT. Make the long piece cut (shown below going from the bottom left to the top right in the photo) first. Then cut to fit the two smaller pieces to complete the X.

Once you get one angle cut, you know that will be the same for the rest of your angles. Just cut to fit each piece just like in this post, and attach through the top and bottom frames with 2 ½″ wood screws. Putty the joints–this will cover over any small gaps 🙂

Step 4: Add Middle Shelf Supports

Once the Xs were in place, I cut two pieces of 2×2 and drilled 1 ½″ pocket holes in each end of both pieces. Using 2 ½″ pocket hole screws, I attached as shown between the front and back middle shelf support.

Step 5: Add Plywood Shelves to X Base Console Table

From the half sheet of ¾″ plywood, I cut two panels to use for the shelves. I have a super helpful post here on how to cut down plywood sheets. I drilled ¾″ pocket holes along the edges of the panels and attached in place using 1 ¼″ pocket hole screws like shown here making sure the plywood is flush to the top of the supports.

Step 6: Add Top to X Base Console Table

You can check out my post here on how I build table tops. In this case, I made the top 53″ long and 23″ deep. I cut two 2×8 boards and one 1×10 board down to about 53″ long and glued them together to make a panel. You can read about how I build table tops in this post here.

Once the glue was dry, I trimmed the edges smooth using a circular saw and sanded the top to even out any high or low spots. Then, I placed the top on the base so that it was centered left and right and was flush on the back side. I used 2 ½″ wood screws to screw the top in place through the top 2×2 supports on all sides.

Step 7: Finish the Console Table

Now all that’s left is a good sanding, stain and poly! I stained this table with Minwax Early American and gave it a few coats of Minwax Polycrylic once the stain dried.

.

And here it is!

Don’t you love those Xs on the sides?? This table makes a simple, but beautiful way to store blankets and pillows, baskets, books, pictures, etc. I would love one in my living room…if only I had space for one haha.

This was actually made for a friend’s bedroom to store family quilts on. It’s perfect for that!

So what do you think?? Which style fits you better? The original X base console table, or this X base console table with middle shelf?? Don’t forget the plans if you’d like to build your own.

And if you haven’t already checked out the tutorial for that awesome, huge, wooden wall clock, check it out here 🙂

.

Also, I would LOVE it if you’d pin this for later! 🙂

Until next time, happy building!! 🙂

I love this table table! I think the 23″ depth would be a touch too deep for my application. Do you think reducing it down to 20″ would still work for the x design on the sides? Also, I’m a little confused about the material list. You posted 1 2x8x18 1 and 2x10x10 would be needed, but I’m not seeing where all of that material is used for the 23″ deep top.

Thank you!

You can totally make the piece narrower, it’ll just change the angles on the Xs, but that’s not a big deal. I’m sorry, I had a typo on the materials–it should be one 2x8x8 and one 2x10x10. You’ll cut the 2×10 to get two 53″ pieces and cut one 53″ piece from the 2×8. When you glue that together, you get the 23″ deep top.