In this post, I will cover the various sizes and styles of Kreg pocket hole jigs and the pros, cons and features of each.

At the end of the post, you’ll be able to determine which Kreg jig (or combination of jigs) is best for your budget, your projects, and your workshop!

My go to brand for all things pocket holes is Kreg Tool. I’ve been using Kreg pocket hole jigs for years.

But, they have several versions of pocket hole jigs and I know it can be a bit confusing to understand the differences between them all and when to use which.

So first, let’s break down the seven versions of pocket holes jigs Kreg offers.

*This post contains affiliate links. See policies.

Kreg Pocket Hole Jig Models

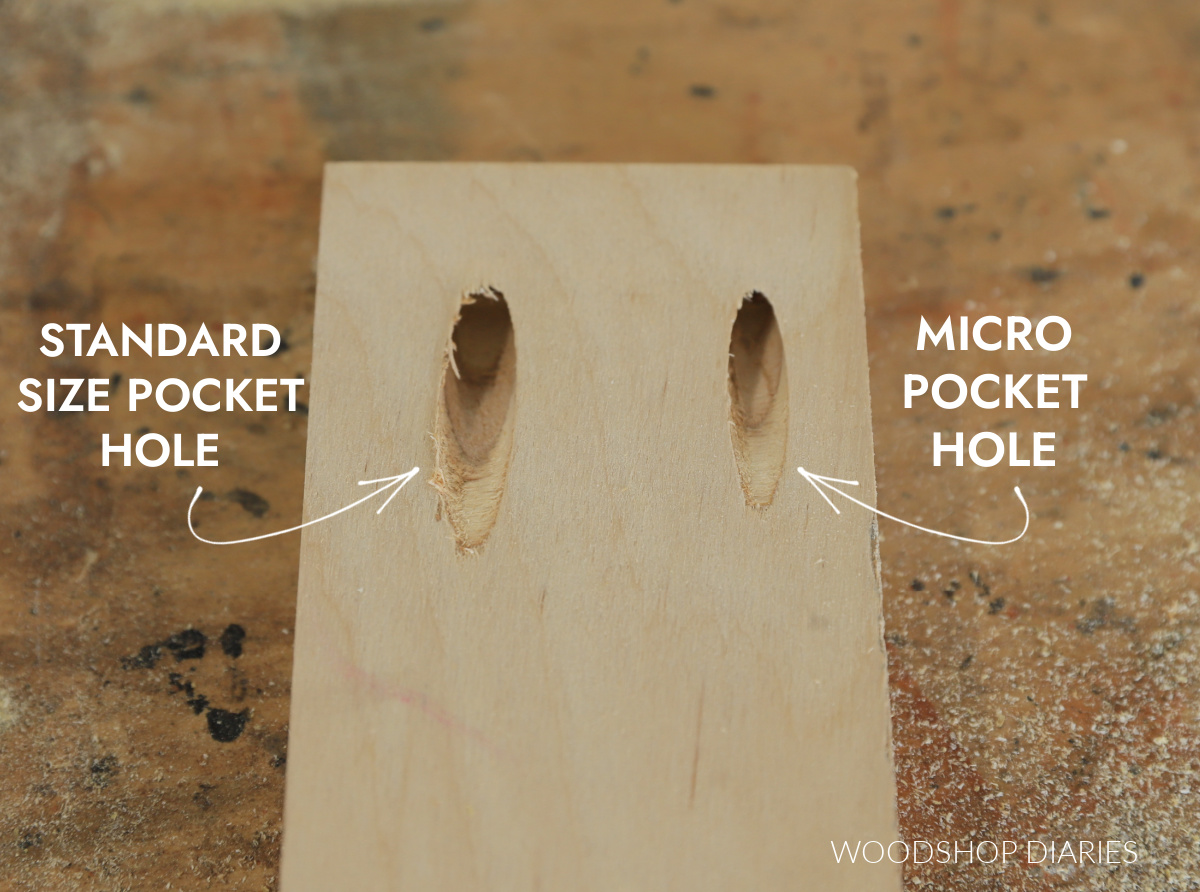

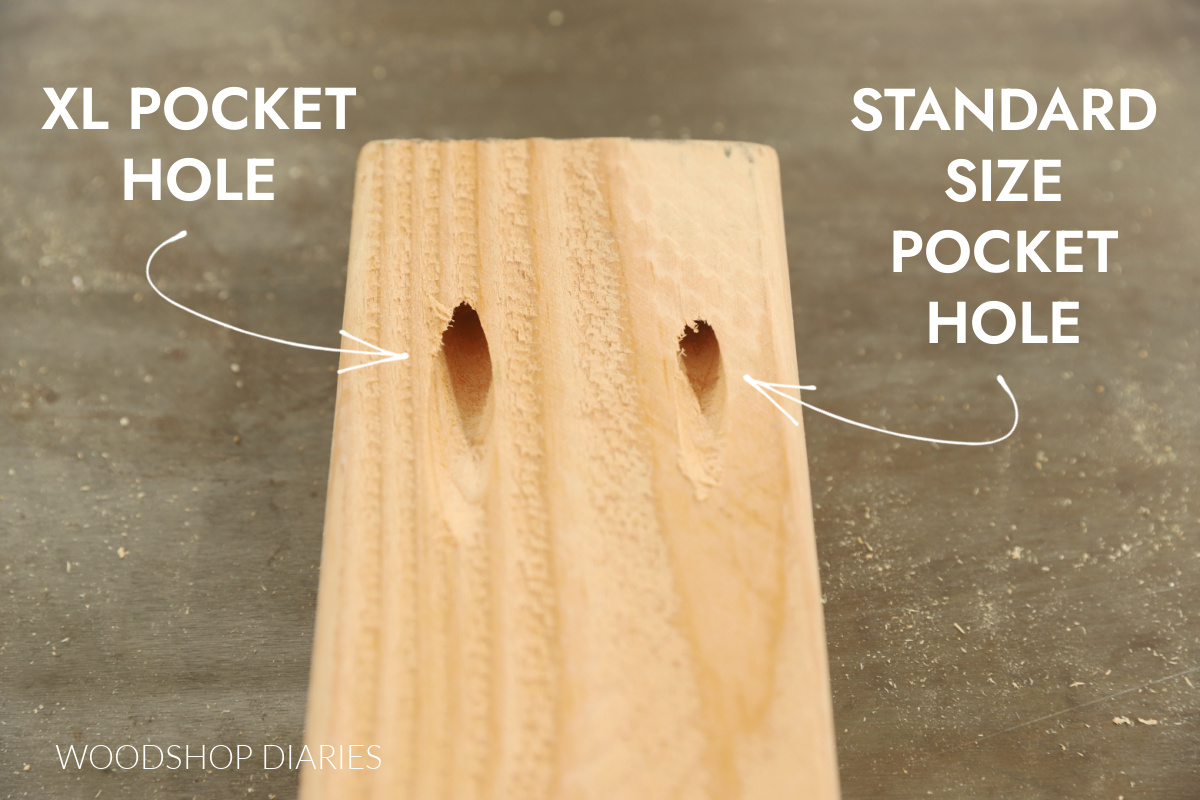

There are three “sizes” of pocket holes: micro, standard, and XL. The “sizes” are based on the diameter of the pocket hole.

The most commonly used pocket hole is ⅜″ diameter. This is what I’m referring to as the standard and are the most versatile. The micro pocket hole is smaller and the XL is larger.

Kreg makes one version of micro jig, 5 versions of standard size pocket hole jigs, and one version of XL jig. They’re listed below.

Kreg Pocket Hole Jig Models:

Back in 2020, Kreg came out with two new pocket hole jig options (the 520 and the 720) and discontinued one of their older models (the K5). The K4 is an older model that is still available for purchase, but I suspect it will eventually phase out.

So what’s the difference between the micro, standard, and XL jigs? The main differences are the size of the pocket holes they make and the thickness of material/type of screws it can be used with.

It makes sense that the smaller pocket holes are for thinner materials and use smaller screws and the larger pocket holes are for thicker materials and use larger screws.

The table below gives a quick overview. But I’ll discuss each jig in more detail below.

| Pocket Hole Diameter | Material thickness | Screw Type | ||||

| ½” | ¾” | 1 ½” | 3 ½” | |||

| Micro | 19/64” | √ | √ | Pan head | ||

| 320 | ⅜” | √ | √ | √ | Washer head | |

| 520 | ||||||

| 720 | ||||||

| K4 | ||||||

| Foreman | ||||||

| XL | ½” | √ | √ | XL | ||

Here’s a quick comparison video, too, if you prefer to watch:

For more information on drilling pocket holes, check out this guide for how to use a pocket hole jig here.

Pocket Hole Jig Parts and Accessories

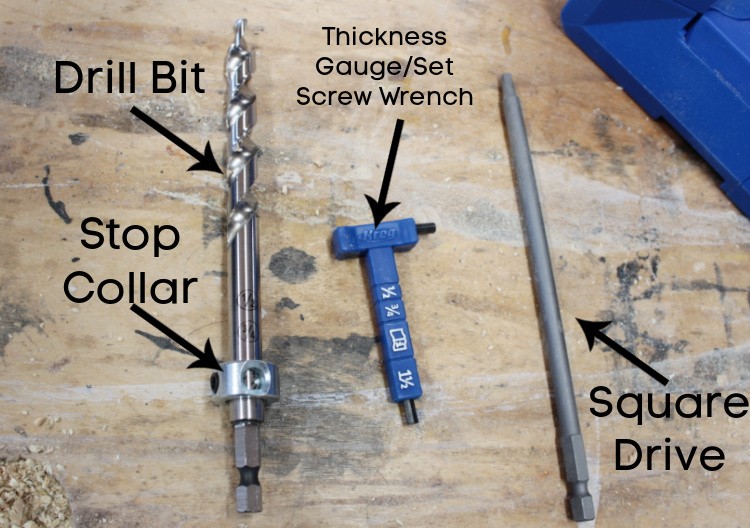

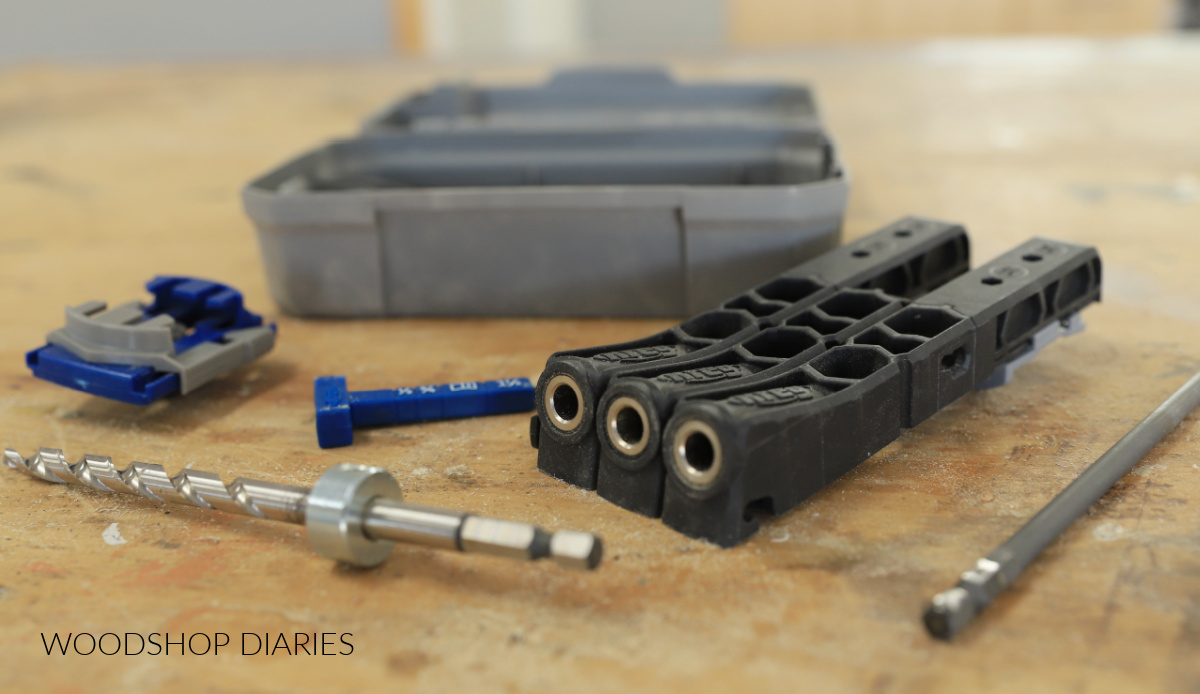

Just a quick FYI–each pocket hole jig comes with a drill bit, stop collar, square drive bit, and a thickness gauge that doubles as a hex wrench for the stop collar set screw.

You can also purchase these pieces individually as spares/replacements as well. Find the drill bit, stop collar and wrench here, and the square drive bit here.

Keep in mind that the micro, standard and XL drill bits are different sizes, so you’ll need to make sure you’re using the right drill bit for the right jig.

Jump to:

The Kreg Micro Pocket Hole Jig

The Kreg Micro pocket hole jig is the smallest jig available. It’s the only stand alone jig that allows you to drill micro size pocket holes.

The micro jig is designed for use in ½″ and ¾″ material and makes pocket holes 33% smaller than standard–see image above for comparison.

It’s quick to set up, small, lightweight and easy to move around your workpiece in order to drill your pocket holes. But, you will need an additional clamp in order to use this jig.

You may be wondering what the advantage of this jig is over the standard size models because those jigs also work with the same material thickness. And that’s a good question!

These smaller pocket holes require you to use smaller pan head pocket hole screws and greatly reduce the risk of splitting or cracking on thin and narrow lumber.

That said, this is not the most versatile option and I don’t recommend it if you’re only looking to buy one pocket hole jig.

The micro makes a great addition to your toolbox if you routinely build with 1x2s or 1x3s or ½″ plywood, but it probably shouldn’t be your only jig. Learn more about how to use the Kreg Micro Jig here.

I recommend the Kreg Micro for

- Someone who already has a standard size pocket hole jig

- Workshops who use ½″ material regularly

- Workshops who routinely build with 1×2 and 1×3 material (especially if it’s hardwood)

Kreg Micro Pros

- Makes smaller pocket holes–less likely to split thin and narrow lumber

- Inexpensive

- Easy to set up and use

Kreg Micro Cons

- Only works with ½″ and ¾″ lumber

- Requires an additional clamp to use (not self clamping)

- Has to be moved and repositioned between every hole (not the most efficient)

The Kreg 320 Pocket Hole Jig

The Kreg 320 pocket hole jig is the smallest standard size pocket hole jig available. It’s great for beginners who are just getting familiar with using pocket hole jigs and don’t want to make a large upfront investment (it’s only about $40).

It’s quick to set up, small, lightweight and easy to move around your workpiece in order to drill your pocket holes. But, you will need to purchase a clamp in order to use this jig.

The Kreg 320 is a standard size jig, so it works with lumber ½″, ¾″ and 1 ½″ thick and is made to be used with regular washer head pocket hole screws. Note that screw length will vary by application.

The Kreg 320 is a really handy jig to have in the shop, but it’s VERY basic. There are no bells and whistles. It’s more labor intensive than other jigs and more time consuming as you have to unclamp, move, re-clamp every time you drill a hole.

It’s not made to be stationed on the workbench, and drilling is usually done in a horizontal motion like you see above. Personally, this tires my arm out pretty quick, so I wouldn’t recommend it for drilling a ton of pocket holes at a time.

But for very long boards or large plywood panels that would be difficult to get into an upright jig, this is a pretty valuable jig to have on hand.

I’d recommend the 320 Kreg Jig for

- Workshops that only use pocket holes occasionally

- First time pocket hole jig users

- Tight budgets

- Workshops that need to drill pocket holes on large panels or long boards

Kreg 320 Pros

- Inexpensive

- Portable

- Easy to set up and adjust for different materials

- Great for large/long boards/panels that would be difficult to use on upright jigs

Kreg 320 Cons

- Requires an additional clamp

- Can’t be stationed on a workbench

- Time consuming to move and re-clamp between each hole

- Hard on your arm to drill horizontally over and over

Additional Kreg 320 Features to Take Note Of

The 320 jig is designed to “break apart” and “add on to.” One of the cool features of the jig is that you can purchase additional drill guides to snap onto the jig to make it wider–or remove them to make it smaller.

The Kreg 520 Pocket Hole Jig

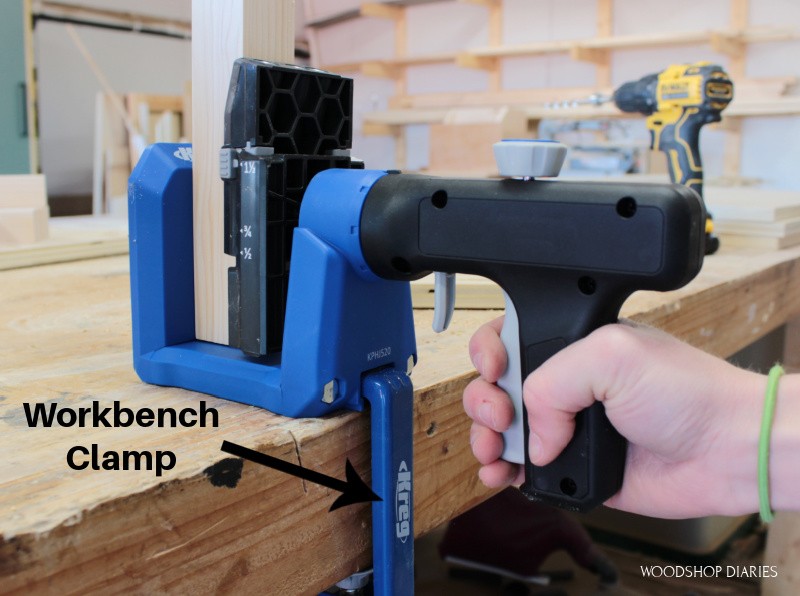

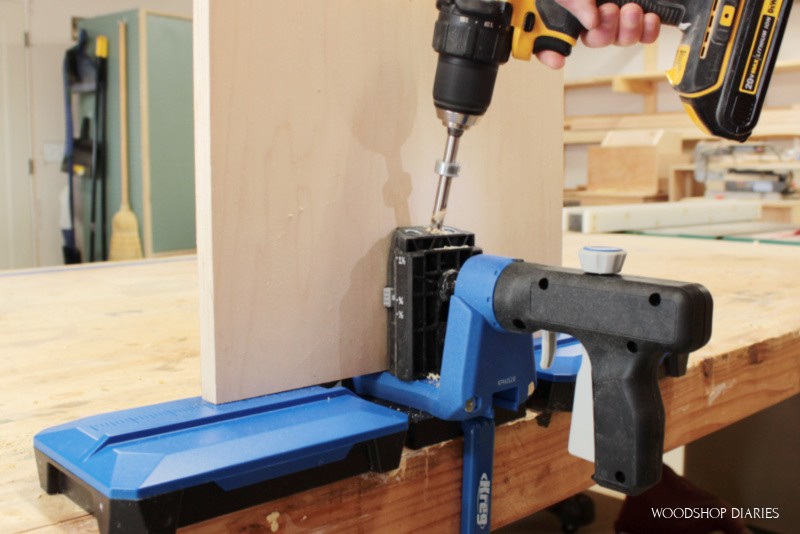

The Kreg 520 is a step up from the 320. It’s still fairly small, and portable, but it does come with its own built in trigger clamp–which is a really cool feature on this new jig.

It’s a little more expensive than the 320 (it’s about $100), but it is quicker and easier to move around your workpiece with the built in clamp function.

As hand held pocket hole jig, you clamp it where you want to drill your hole, then unclamp and move it around your piece.

The trigger clamp is a really nice feature they added to this series and it has a little lever for a quick release when you’re ready to move it.

The 520 Kreg Jig is kind of like a “best of both worlds” pocket hole jig.

It is a portable, hand-held jig like the 320, but it has the capability of clamping onto a workbench similar to the 720 for upright clamping. But, for that, you do need to purchase the pocket hole clamp separate (but it’s only about $15, so it’s well worth the investment).

Just like with the 320, it’s a great option for beginners, small shops and for large panels that would be hard to maneuver around a workbench.

Personally, if you only buy ONE pocket hole jig for your shop, this is the one I’d suggest since it’s so versatile.

I recommend the Kreg 520 Pocket Hole Jig for

- First time pocket hole jig users

- Woodworkers looking for a step up from the 320

- Small workshops that need the best bang for their buck and don’t have room or budget for large or multiple jigs

Kreg 520 Jig Pros

- A “best of both worlds” option that allows for both hand held and workbench mounted drilling

- Small and lightweight

- Built in trigger clamp and quick release function

- Budget friendly

Kreg 520 Jig Cons

- Requires an additional clamp if you want to mount it to the workbench

- Not as many bells, whistles and features as the larger 720

Additional Kreg 520 Features to Take Note Of

If you wanted to pick up a Kreg 520 pocket hole jig, but wanted to add a few extra bells and whistles, you can purchase the Docking Station (about $50) that is compatible with both the 520 and the 720 jigs.

This docking station includes the pocket hole clamp, some support wings (that double as storage boxes for the drill bits, clamp and accessories) to help support larger pieces during upright drilling, and an adjustable stop block.

This add-on just gives some extra functionality to the jig in the workbench mounted position.

The Kreg 720 Pocket Hole Jig

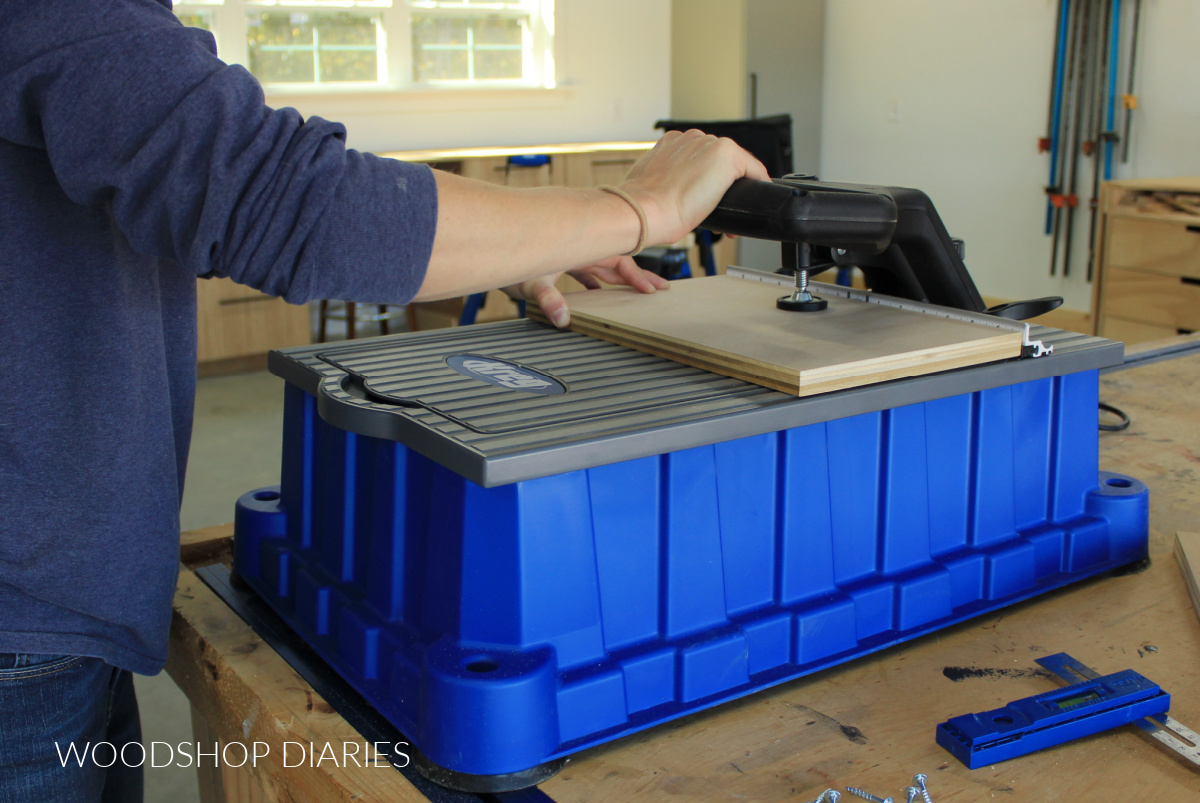

The 720 Kreg Jig is more of a “stationary” version. It’s larger and more expensive (about $130) but, it’s also quicker and more efficient. This is my personal favorite jig and the one I use in my shop the most.

With the 720, instead of moving the jig around the piece, you move the piece around in the jig.

The 720 is a great option if you drill a lot of pocket holes and need a quick and efficient set up. Since you don’t have to unclamp and move the jig for every hole, it’s less labor intensive and much quicker for high production workshops.

This larger 720 jig comes with built in fold out/in extension wings for additional support for large boards or plywood panels.

And just like with the 520, you can purchase a pocket hole clamp to clamp this jig to the workbench–or add on a docking station that includes the clamp, additional support wings and an adjustable stop block.

The Kreg 720 Jig also comes as a 720 Pro kit that includes the jig and the docking station together along with vacuum dust attachments at a discounted price than if you purchased them separately.

This jig actually can mount in multiple positions so you can drill both vertical (shown above) or horizontal (shown below in two directions).

And, so you don’t lose all your accessories, it comes with onboard drill bit storage on the back side. The 720 has all its features built right into it, so it’s really an all-in-one package.

One of the coolest features of this new 700 series jig is that you don’t have to set it up for your board thickness. On the other jigs, you have to set BOTH your drill bit stop collar AND your jig up for the correct board thickness.

But, the new 720 AutoMaxx clamp feature sets the jig for you (for materials ½″ up to 1 ½″ thick), so all you have to do is adjust the stop collar on your drill bit.

RELATED: Check out this post to learn how to use a pocket hole jig and adjust the drill bit properly.

Personally, I only use ¾″ and 1 ½″ material with my pocket holes. So, I recommend purchasing an additional drill bit so you can keep one set up for ¾″ material and one for 1 ½″ material. Then, since this jig adjusts itself, you can just swap out the drill bit when you change materials and you’re good to go.

.

This pocket hole jig set up also allows you to swap out the drill guide for a plug cutting attachment (sold separately).

RELATED: Check out how to drill your own pocket hole plugs with the plug cutting kit here.

You can also swap the standard pocket hole size drill guide for a micro drill guide. But, honestly, for the price of the drill guide attachments and the pain it is to swap them, I’d prefer to just buy the separate micro jig than to buy the additional drill guide.

With all the bells and whistles this 720 jig offers, the biggest downside to it that I can see is that it’s fairly large and not quite as easy to move around if you needed to drill pocket holes in really long boards or large panels.

I recommend the Kreg 720 Jig for

- Workshops that drill a lot of pocket holes

- Shops with plenty of work surface space

- Beginner to Advanced pocket hole users

- Woodworkers looking for a jig for the long term

- Anyone interested in cutting their own pocket hole plugs

Kreg 720 Jig Pros

- Auto-adjusts for board thickness

- Allows you to use plug cutting guide to cut your own pocket hole plugs

- Quick and efficient for high production pocket hole drilling

- Built in extension wings for large board support

- Onboard bit storage

- Can clamp in both vertical and horizontal positions

Kreg 720 Jig Cons

- More expensive than the 320 and the 520

- Takes up more work surface space

- Doesn’t function as a portable hand held jig for large boards if needed

The Kreg K4 Jig

The Kreg K4 pocket hole jig is an older version that I actually didn’t use but just a few times.

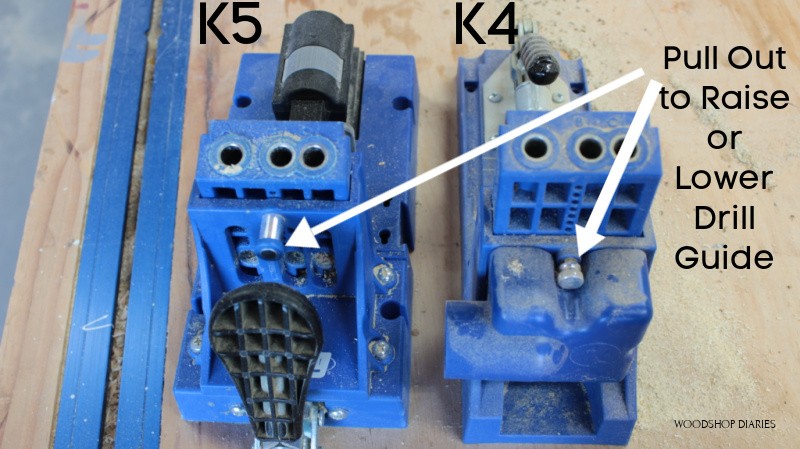

Before Kreg came out with the 720, the K4 and K5 jigs were kind of the go-to pocket hole jig models. I used the K5 for most everything (I preferred it over the K4). Both of these jigs were very similar but, as I mentioned before, the K5 has been discontinued.

For some reason, the K4 is still available, but has lost much of it’s popularity to the 720.

The K4 has a built in clamp (a lot like the 720), but it doesn’t automatically adjust to different board thicknesses. You have to manually set the board thickness on the jig before clamping.

It’s SLIGHTLY less expensive than the 720 but around the same price as the 520. Personally, for the price, I’d opt for either of these newer options before I’d buy a K4–but of course, that’s just me.

The K4 has been around for a while and is definitely a tried and true, durable jig, but it just doesn’t offer some of the convenient features of the newer models.

So personally, I don’t recommend the K4–not that it’s a bad jig–but I think there are better options available for the price.

Kreg K4 Pros

- Built in clamp

- Durable, but still lightweight/easy to move around

- Budget friendly

Kreg K4 Cons

- Have to manually adjust board thickness on jig

- Similar design, but not as many features as the 720

- Not designed for multiple drilling orientations like the 520 and 720

The Kreg Foreman

Now, I can’t say a lot about the Foreman as I don’t personally use one. I had one for a brief time, but rarely used it. BUT, it’s an option I’d only recommend for high production pocket hole drilling.

It’s pricey (about $450) and takes up a significant amount of space, and has to be plugged in (the drill is built into it, so it needs a power source). So it’s probably not a great option for anyone just starting out or for small workshops that only drill the occasional pocket hole.

But if you drill a lot of pocket holes, it’s worth considering and could be a really great investment and time saver for your shop.

You can check out more about the Foreman on Kreg’s website here.

The Kreg XL Pocket Hole Jig

The Kreg XL Pocket Hole Jig is the only stand alone jig that allows you to drill XL sized pocket holes.

The XL jig is designed for use in 1 ½″ and 3 ½″ material (which is 2x and 4x lumber) and makes pocket holes quite a bit larger than standard–see image above for comparison.

It’s quick to set up, small, lightweight and easy to move around your workpiece in order to drill your pocket holes. But, you will need an additional clamp in order to use this jig.

The XL pocket hole jig is the only option available that allows you to drill pocket holes in 3 ½″ thick material. So it’s a must have if you plan to use pocket holes in 4×4 lumber.

It’s made to be used with XL pocket hole screws, which are quite a bit larger than the standard washer head pocket hole screws. While this makes super strong joints in 4x4s, the larger screws do run a higher risk of splitting when used in 2x material.

Personally, I only use the XL jig when working with 4x4s and stick with standard pocket holes in 2x lumber. But if you need extra strength, it’s a great option to have.

Much like the Kreg Micro, it’s a great addition to the workshop, but isn’t the most versatile. So if you’re only getting one jig, the XL probably isn’t the best option. Learn more about how and when to use the Kreg XL pocket hole jig here.

I’d recommend the Kreg XL Jig for

- Someone who already has a standard size pocket hole jig

- Workshops that often use 2x and 4x lumber

- Workshops that often build outdoor projects

Kreg XL Jig Pros

- Inexpensive

- Easy to set up and use

- Best jig option for thick materials/large builds

Kreg XL Jig Cons

- Requires an additional clamp (not self clamping)

- Only works with 1 ½″ and 3 ½″ thick material

- Requires larger, more expensive pocket hole screws

Final Thoughts About Choosing a Pocket Hole Jig

When you are looking at adding new tools to your workshop, I know it can be stressful when you aren’t sure what’s best for your situation.

I hope this helps clear up the difference between the Kreg jigs available and make a better, informed decision on which Kreg Jig to buy for you and your workshop.

If you’re interested in learning more about pocket holes, check out these posts you might find helpful:

- How to use a pocket hole jig

- 4 ways to fill your pocket holes

- How, when, and why to use the Micro Pocket Hole Jig

- How, when, and why to use the XL Pocket Hole Jig

Are DIY projects your thing? Sign up for our newsletter for priority access to the latest projects and build plans!

And if you’d like to save this guide for later, be sure to pin it or share to your favorite social channel!

Until next time, friends, happy building! 🙂